Composite manufacturers are being challenged to reduce cost, increase throughput, and improve first-time quality of composite aerostructures used to build modern air vehicles.

The problem is current state-of-the-art composite manufacturing processes involve expensive autoclave, ovens, and manual processes that present barriers to achieving cost and volume goals.

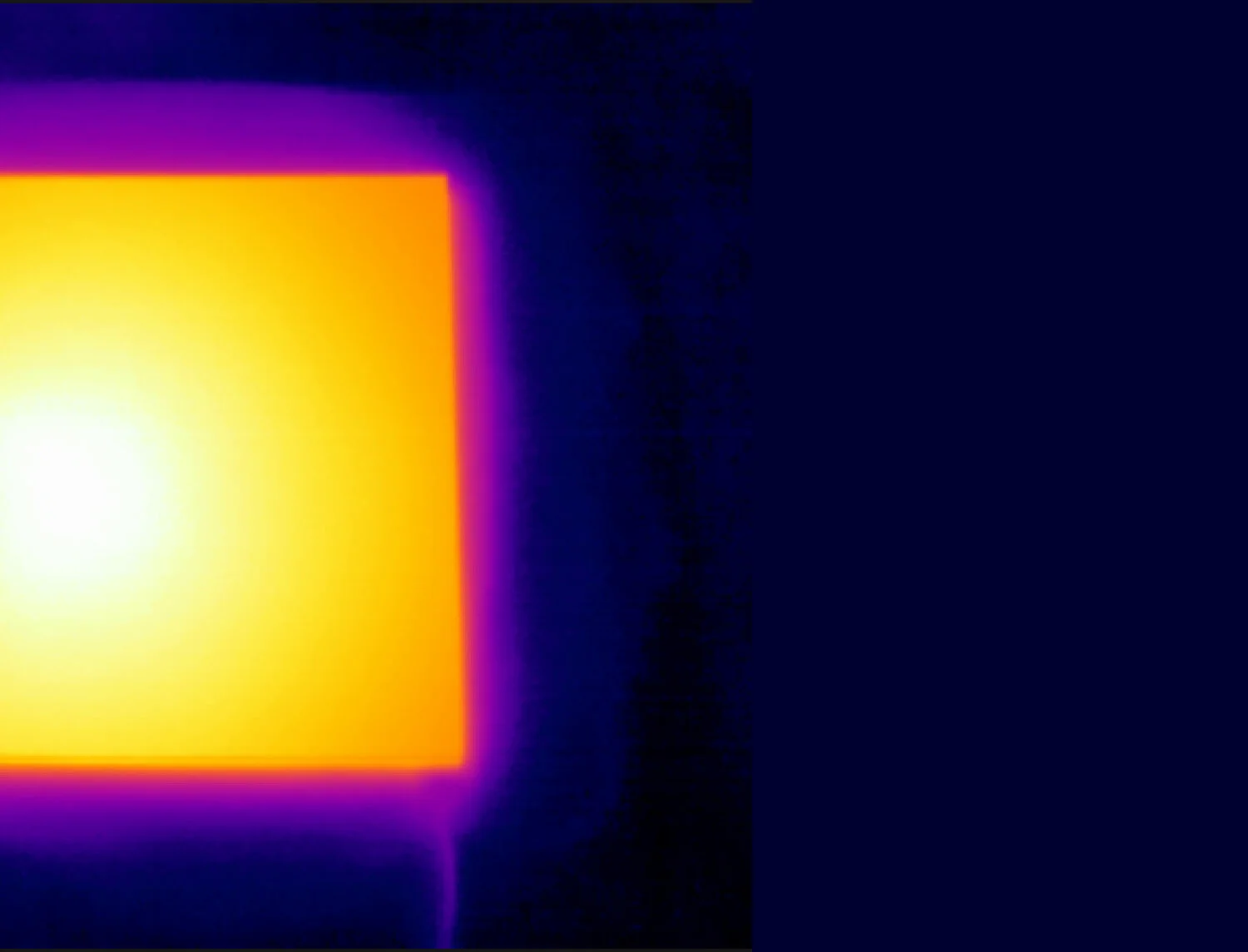

For this reason, we developed VeeloHEAT, a new advanced heating technology that is changing the way composites aerostructures are fabricated, assembled, bonded, and repaired. The technology is based on a proprietary heating material, and engineered designs that are tailored to meet customer's thermal and power requirements, and enable out-of-autoclave (OoA) and out-of-oven (OoO) composite processing. VeeloHEAT is currently used by the aerospace composites industry to bond multi-million-dollar composite aerostructures, accelerating adhesive cure, composite repair, improving heated debulk processes, and heated tooling.

Learn about our NEW OoA Composite Processing Tool!

HyVARCVeeloHEAT is the new technology and is a hybrid Invar and composite mold with integrated VeeloHEAT® technology.