Description

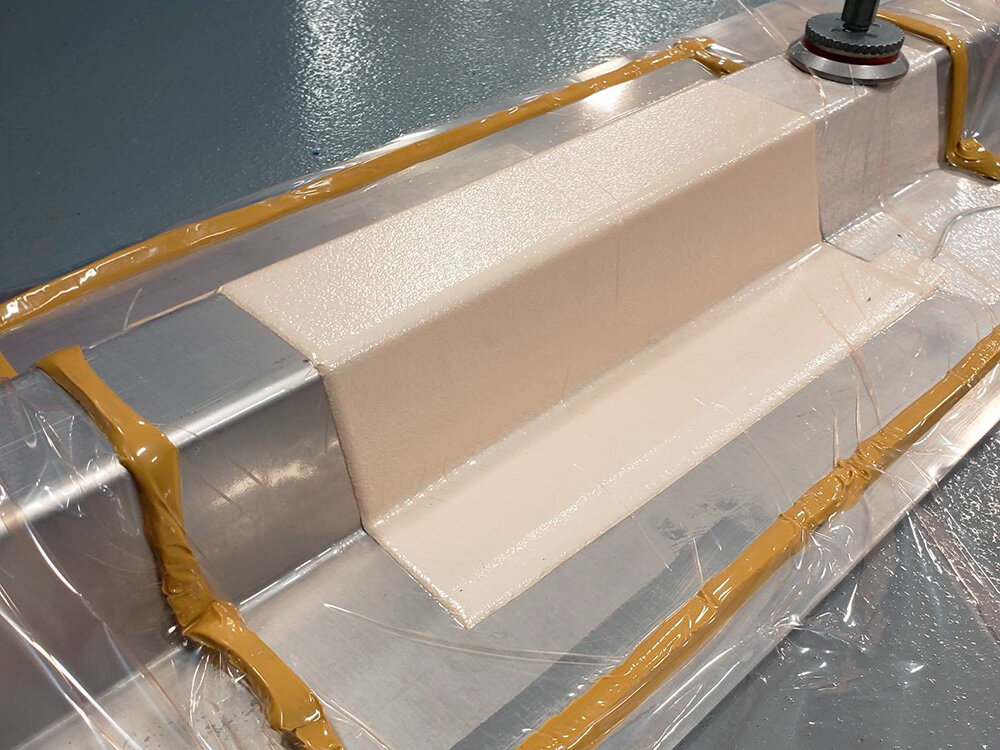

Leveraging Veelo's heat technology capability, the VeeloHEAT Caul allows for in-situ hot debulk. Building on existing bagging procedures, the addition of VeeloHEAT Caul allows companies to stay out of the oven by afford heated debulk at the tool during layup, which substantially improves throughput.

Features

Lightweight, uniform heating solution for advanced composites

Durable, damage-tolerant, heated caul

Tailored heating, power density

FKM-based heater system for high performance and material compatibility

Clean room elevated tool heating — increase tack during layup

Autoclave cycle time reduction

Benefits

Electrically efficient, fast heating and cooling

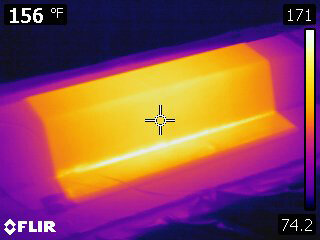

Highly uniform across large surface areas

Fatigue resistant

Custom shapes

Scalable for large tools

Technical Specifications

Temperature range: 100F–400F (500F intermittent)

Applications

Out-of-oven heated debulk

Out-of-autoclave composite processing

Accelerated cure in autoclave processing

Net-shaped composite repair

Secondarily bonded heater for metallic tooling

Secondarily bonded heater for electrothermal de-icing